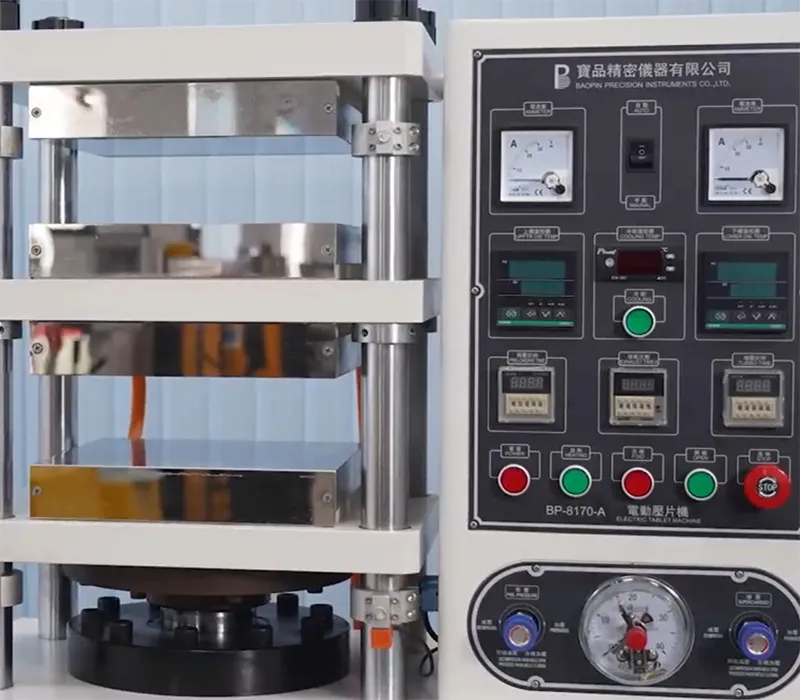

- 20 Ton Capacity (others on request)

- Instrument control

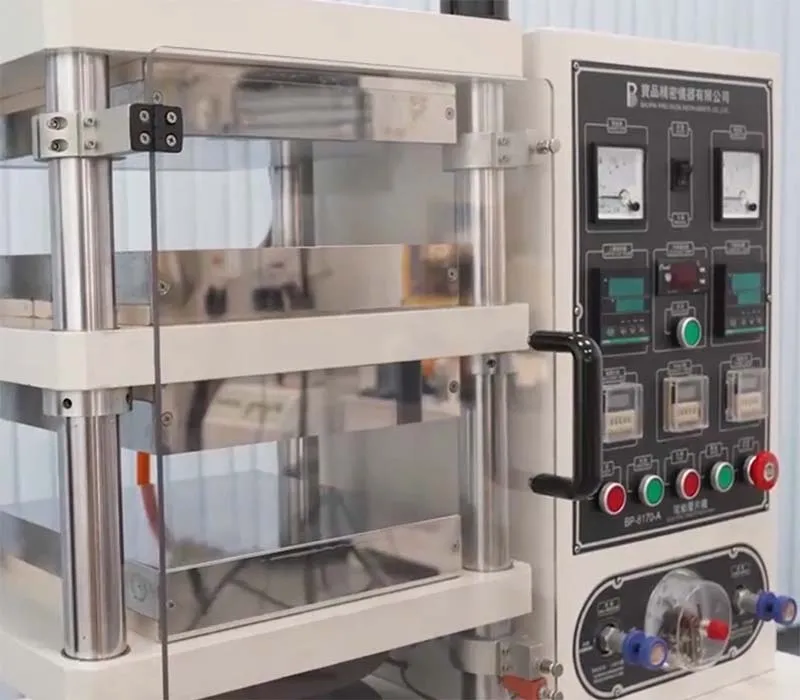

- Double set of pressing platens

- Electric heating of upper set of platens, water cooling of lower set of platens

The raw material is placed into the mold and compressed between the electric heating platens of the hydraulic press under pressure and temperature to form the material for testing. This process serves as the basis for large-scale production in the factory.

The vulcanizing press uses mobil 32# anti-freezing hydraulic oil, with a maximum pressure of 20 tons (other options available). When the product is vulcanized and molded, the oil pump motor stops working. It features automatic pressure compensation and delayed shutdown for maintaining pressure. The degassing time, number of cycles, pressure, and temperature can all be freely set. With both manual and automatic working modes, it is easy to operate, reliable, and durable.

Applications

Compression molding and vulcanization of materials such as plastics, rubber, and resin.

- Capacity

20 tons (others on request) - Temperature range

Room temperature to 300℃ - Temperature control

LED digital display, push button input, digital readout - Timer control

LED digital display, 0.1s-99m-9.9hr (settable time) - Heating platen size

300×300mm - Cooling platen size

300×300mm - Open daylight

70mm - Pressing platens

2 sets of pressing platens, electric heating of upper set of platens, water cooling of lower set of platens - Oil Pressure System

The GPY oil pump drives high-performance electro-hydraulic injection into a resistance-free oil cylinder to implement an equal rate control mode, featuring automatic pressure compensation and a delayed oil pump shutdown function. - Oil Pressure Media

Mobil 32# anti-freezing hydraulic oil (provided by the customer). - Dimensions (W×D×H)

920×470×1470mm - Power supply

AC380V, 20A, 3-phase 5-wire (power connection port is provided by user) - Weight

approx. 658kg

Please fill the form and our experts will be in touch with you as soon as possible.

- Email: kyle@dgbaopin.com