- 20 Ton Capacity (others on request)

- PLC control

- Single set of pressing platens

- Integrated electric heating and water cooling on both upper and lower platens

The laboratory vacuum press is designed with a high vacuum cover, creating a fully vacuumized environment for compressing and molding materials such as rubber, plastics, and composite materials.

By integrating the vacuum system with the heating platens, it effectively removes trapped air and volatile substances, ensuring the formation of strong, durable materials with superior quality.

Reach out today to discover how our laboratory vacuum press can improve your material processing and production efficiency.

Technical Data

- Capacity

20 tons (others on request) - Temperature range

Room temperature to 400℃ - Temperature accuracy

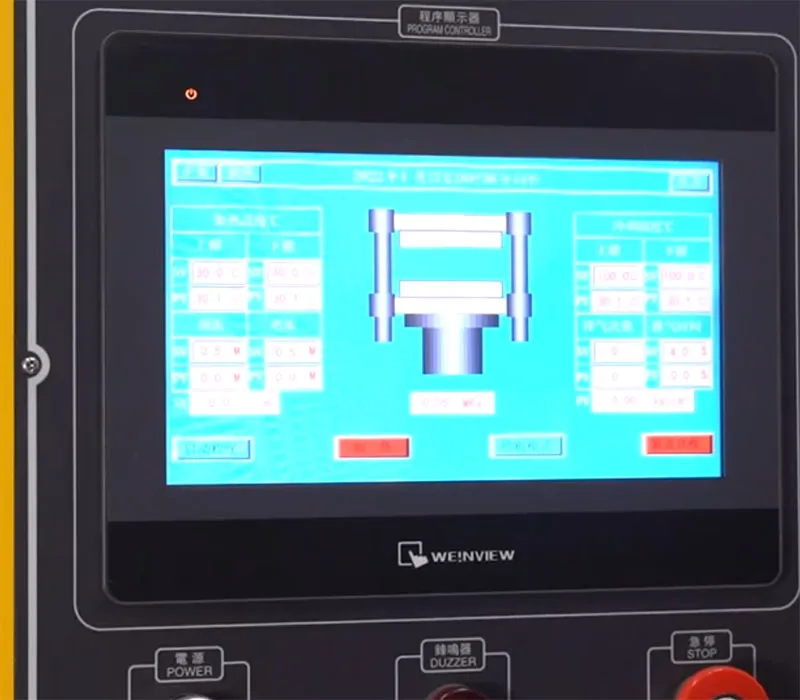

±2℃ - Controller

PLC programmable color touch screen with a man-machine interface operating system. The intuitive vulcanization curve interface allows for dynamic display and monitoring of the mold pressure process, and provides control over all mold pressure circulation. - Pressing platen size

300×300×60mm - Open daylight

150mm - Pressing platens

1 set of pressing platen, integrated electric heating and water cooling on both upper and lower platens - Cooling Method

Tap water cooling. After the heating process is complete, the system automatically switches to the cooling process and operates at full pressure (without opening the mold). (Water connection port supplied by the customer). - Oil Pressure System

The proportional hydraulic flow valve circulation control system offers automatic pressure compensation, pressure maintenance, and delayed oil pump shutdown. It features a dual-speed working mode, utilizing high approach speed for low pressure and low approach speed for high pressure. Multiple exhaust times can be set to ensure that the template pressure reaches saturation. - Dimensions (W×D×H)

950×500×1470mm - Power supply

AC380V, 20A, 3-phase 5-wire (power connection port is provided by user) - Weight

approx. 658kg

Can we help you with your project?

Please fill the form and our experts will be in touch with you as soon as possible.

- Email: kyle@dgbaopin.com